Hauser has a special place for me as the first great guitar I held, played and examined was a guitar that Hauser made in 1935. Once, as a young student in London, I was chatting to Colin Cooper, then the editor of

Classical Guitar magazine. He mentioned that Victoria Kingsley had a Hauser, and a Bouchet. I duly wrote to her, asking if I could see the guitars, to which she kindly agreed. I visited her in Hampstead one dark winters evening and she very trustingly left me alone with her instruments for as long as I wished. She also provided me with a cup of delicious Earl Grey tea, served in a delicate china cup. Sadly the light was bad, and my photographic equipment primitive. The picture above is the only one I have. I took notes and measurement, expecting a great secret to be revealed: I am still waiting for that revelation.

Below is a picture of a page of the notebook into which I made notes and measurements, and the note from Victoria Kingsley. They are resting on the template I made of this guitar, and that I still have and use in the workshop.

I regret that the guitar was strung with the oldest strings imaginable, but what I regret more is not talking more to Miss Kingsley who had led the most remarkable life, which was eventually to run to 100 years. I will always be grateful to her for her generosity and trust in allowing me to learn from this beautiful guitar.

Hauser is one of those names that in guitar making circles has gained almost mythical status. Undoubtedly one of the most copied makers of the 20th century, his guitars have been used by hugely influential players, of which Andres Segovia and Julian Bream are the most notable. The prices that his guitars fetch are massive, and many are bought by collectors rather than players.

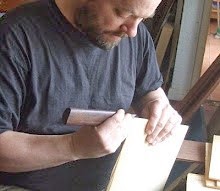

I have recently been going through my archive of papers and photographs and taking the opportunity of throwing quite a lot of material out. The pictures in particular have provoked quite a few trains of thought; none more so than these pictures of a Herman Hauser guitar that I worked on 4 or 5 years ago. Built in 1941, this guitar is pretty representative of Hauser's output and includes his characteristic rosette, headstock and inlay. Whilst it was in the workshop I took the opportunity to take detailed measurements and from these produced a full size working drawing. There were no surprises with this guitar, and anyone who is familiar with drawings of Hauser guitars by Richard Brune and Jeff Elliot will immediately recognise the details on my drawing.

.

The 1941 guitar was a pleasure to have in the workshop. The back and ribs were Indian rosewood, a timber that I have seen on a number of Hauser's instruments. The neck was mahogany with a tight, precise V-join. The top was of good quality but had a number of previously repaired cracks. It was thicknessed to 2.5 mm, thinning to 2.2 around the periphery. It should be noted that the instrument had been refinished, although I felt that the top had not been substantially altered. And how did it sound? Well-balanced, refined, not loud (nor quiet), a deep bass register that had not become flabby...to be honest I suspect it was past its best, but it is still a fine guitar. A hugely important piece of classical guitar history but no longer a concert guitar in my opinion.

2 years ago I was walking through Central Park in New York, wondering whether I had time to fit in a visit to the Metropolitan Museum of Art that was close by. They hold a fabulous collection of guitars, including Segovia's '37 Hauser, which he described as 'the greatest guitar of our epoch'.

The more I thought about it, the more cross I became with that statement and began to see it as rather destructive. I suspect Segovia was saying more about his own involvement with this guitar than anything else but it set the seeds of a grand distortion.

I, like many others, have been brought under the indefinable spell of Hauser, and have certainly played and heard some beautiful guitars that he made. He understood the materials he was working with, and he understood the nature of the instrument he was making. However, Hauser's qualities remain elusive and one wonders sometimes how his, or any maker's status for that matter, should really be evaluated.

4

4