I have just had a clear out of tools (mainly carving gouges) as I needed the room. I have accumulated so many tools over the years, and have also given a good few away. I am getting to the point where I have what I need and no more. This is a good place to be.

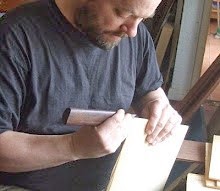

I have just had a clear out of tools (mainly carving gouges) as I needed the room. I have accumulated so many tools over the years, and have also given a good few away. I am getting to the point where I have what I need and no more. This is a good place to be.The center piece of this picture is my Record No. 5. When I started learning guitar making at the London College of Furniture in 1984, Herbert Schwarz my tutor, sent me off to acquire a plane. That part of the east end of London had once been the centre of woodworking trades and there were still a handful of reminders from those days. Crispins Veneers in Curtain Road for example,was a wonderful example of old fashioned supplier. Contained in a ramshackle 19th century warehouse, it was full of wonderful exotic veneers, and when you had selected what you wanted, it was carefully rolled in cardboard and tied with string. Invoices were hand written, standing at a lectern and if they had been scratched out using a quill, the picture would have been complete.

One grey October day I walked up Old Street to Tyzacks tool shop and bought this plane. It wasn't a shop that you wandered round; you went up to the counter and asked for what you wanted, and waited while a man in a brown coat disappeared into the back of the shop to find the tool you had requested. I have had this plane since that day and it is the tool that my workshop centers around. Although it is just a standard mass produced plane, it is a tool that I implicitly trust; I know exactly what I can do with it; it works perfectly.

The engineers square is commonplace, but always in use and rarely in its space on the tool rack. For me this is the perfect size for most of my work, although I have a bigger one, and indeed, a smaller one.

The brass purfling cutter was made at the LCF, and if my memory serves me correctly, it was from the skilled hands of fellow student Nick Swann. Different makers swear by different designs. I like the simple functionality of this one and I am now very used to it.

And finally, at the bottom of the picture, a 1 inch Sorby paring chisel. It was Michael Gee who turned me on to paring chisels and now I wont use anything else. The length of the blade allows you to keep some distance between you and the work and gives even finer control over the cutting edge. Other makers use shorter chisels and do fine work, but this is something that works for me. The smooth boxwood handle feels cool and comfortable in the hand. Looking at the picture leaves me shocked at how much shorter the blade is than when I first bought it; many years of honing have taken their toll. Fortunately I have stockpiled a few of these and so I am confident I have a lifetime supply.

No comments:

Post a Comment