Last night I glued backs on the 2 guitars I am currently building, and today I have been preparing them for binding. The workshop sound system has been pumping out Bob Dylan (and the Carter Family) I don't always listen to classical guitar music you know. It seems appropriate therefore to feature this Martin O-15 which I recently worked on, although I'm not sure that the big Zim ever played one.

Last night I glued backs on the 2 guitars I am currently building, and today I have been preparing them for binding. The workshop sound system has been pumping out Bob Dylan (and the Carter Family) I don't always listen to classical guitar music you know. It seems appropriate therefore to feature this Martin O-15 which I recently worked on, although I'm not sure that the big Zim ever played one.This guitar was made in the 50's and was one of the plainest, simplest guitars that Martin ever made. Top, back and ribs of mahogany, no bindings and the simplest of inlays meant that this was an affordable but quality instrument. Like a fair number of old Martins, this was in need of a neck reset, plus a few other small repairs.

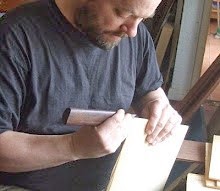

The first part of the neck reset process is to loosen the fingerboard where it is attached to the body. I heat the fingerboard( having removed the frets) and then get in under the fingerboard with a hot palette knife. Once the fingerboard has started to separate, I carefully drive a couple of soft spruce wedges underneath and apply a little water and more heat. This can sometimes be the most taxing part of a neck reset, although this one separated without any great bother.

The first part of the neck reset process is to loosen the fingerboard where it is attached to the body. I heat the fingerboard( having removed the frets) and then get in under the fingerboard with a hot palette knife. Once the fingerboard has started to separate, I carefully drive a couple of soft spruce wedges underneath and apply a little water and more heat. This can sometimes be the most taxing part of a neck reset, although this one separated without any great bother. Just for the record, here is a picture of the inside of the guitar which shows the tidy workmanship inside the guitar.

Just for the record, here is a picture of the inside of the guitar which shows the tidy workmanship inside the guitar. Here is the neck being removed. A 2mm hole is drilled through the 15th fret into the back of the dovetail joint. This allows steam to be driven into the join and so soften the glue. The steam is generated by a domestic coffee maker; the jig and the rubber hose and nozzle are from StewMac. Once the steam has softened the glue, the jig, which puts pressure on the underside of the heel, pushes the neck out of the end block and the neck is removed.

Here is the neck being removed. A 2mm hole is drilled through the 15th fret into the back of the dovetail joint. This allows steam to be driven into the join and so soften the glue. The steam is generated by a domestic coffee maker; the jig and the rubber hose and nozzle are from StewMac. Once the steam has softened the glue, the jig, which puts pressure on the underside of the heel, pushes the neck out of the end block and the neck is removed.The joint is now cleaned and the shoulders of the heel adjusted to achieve the correct angle on the neck. Because of this adjustment, the joint invariably needs packing with slips of veneer although i have seen a fair few Martins that were factory fitted with shims of card and paper.

1 plastic dot was missing from the 5th fret position so I made another one to fit. It is amazing how long it takes to make a small detail like this, but the end result is worth it. I also patched in some very bad fretboard wear. Some repairers simply fill the hole with epoxy, but I like to let in a perfectly matched piece of rosewood. The picture below is somewhat blurred, but you get the idea.

1 plastic dot was missing from the 5th fret position so I made another one to fit. It is amazing how long it takes to make a small detail like this, but the end result is worth it. I also patched in some very bad fretboard wear. Some repairers simply fill the hole with epoxy, but I like to let in a perfectly matched piece of rosewood. The picture below is somewhat blurred, but you get the idea. And here is a shot of the guitar in its finished state, restrung and ready for the next 50 years of music making.

And here is a shot of the guitar in its finished state, restrung and ready for the next 50 years of music making.

No comments:

Post a Comment