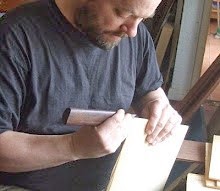

Sunday evening and I am planning out the week ahead in the workshop. The main task tomorrow will be to grain fill Julio's guitar. These are some of the last pictures I will post of it until it is polished and strung up. It is one of those guitars that I am really looking forward to polishing as the woods I selected for it are subtly striking. The picture above shows the guitar being fretted: I use a metal headed hammer and and a soft-faced hammer. The metal hammer for the first tap in and the soft hammer for the final seating blow. Fretting always makes me thing of my old teacher Herbert Schwarz, who, when showing students how to install frets, would almost invariably end up with a flourish of hammer blows -'da dadalada da, bang, bang'! He would them glance around the workshop with a wry smile to see if anyone had noticed. I still do it now and again, even when I am alone in the workshop. I like to think that Herbert notices and smiles, wherever he is.

The metal pincers, used for nipping off the fret ends, were bought when I was a fresh faced student in 1984. Made in China, the were bought from a little hardware shop on Lower Marsh, just behind Waterloo Station in London. They're cheap rubbish really, but they work and are never far from my workbench.

Here is a picture of the fret slots being cut in the ebony fingerboard. The motor is taken from a very cheap table saw (the table and the blade being virtually useless) and a bespoke MDF table build around it. The sliding carriage is the simplest possible but is spot-on accurate. The time saved by using this saw, rather than doing it by hand, is so considerable that I wouldn't want to return to doing it with my specially set Roberts and Lee hand saw, however much I love that particular tool.

And finally, here is the heel cap being glued on Julio's guitar. The Cocobolo bindings look rather fine here; cocobolo is one of my favourite woods for bindings although I am getting a bit low on stock. In the background you can see a fingerboard being glued to another guitar. I use a polyurethane glue for fingerboards and you can see all the squeeze-out foaming around the neck and fingerboard.

Thanks for introducing amazing guitar maker. Guitar makers build amazing guitars that mesmerize the world.

ReplyDelete